- 2024-11-13

- Frida Kutasi

Navigating Certification Process of Ex Product – Challenges of Certificate of Conformity (CoC) Part1

Obtaining certification for Ex products is a crucial step for manufacturers seeking to enter potentially explosive atmospheres. However, navigating the complex certification landscape can be daunting, especially when it comes to obtaining the Certificate of Conformity (CoC). In this post, we’ll break down the key steps, challenges, and best practices to help you secure the CoC efficiently and meet the highest safety standards.

We will begin by comparing the IECEx and ATEX certification processes, highlighting their unique differences and the specific requirements for each. Subsequently, we will delve into the details of the CoC process, including the necessary documentation, sample preparation, and the critical role of the Factory Quality Assessment Report (QAR).

By understanding the challenges and best practices associated with the CoC process, manufacturers can effectively navigate the certification journey and ensure that their Ex Products meet the highest safety standards.

How to Get Product Certificate - IECEx vs. ATEX

Every certification has its certification process, the most common part between them is every certification requires product testing. But now let’s see IECEx and ATEX’s most unique differences.

IECEx Certificate Types and Process

At IECEx there are 3 kinds of options for Ex product certification.

Certificate of Conformity (CoC) – We will detail this certification process because this is the most complex.

A component certificate – This kind of certification process is the same as CoC, but the certified Ex product is an Ex Component. Ex Component is a part of an apparatus or a module, that is not intended to be used alone and requires additional certification when incorporated into equipment or systems for use in potentially explosive atmospheres.

A unit verification certificate – It does not necessitate on-site factory inspections or continuous surveillance. However, each unit must have a unique identifier on the certificate. If multiple units are included on a single certificate, all serial numbers must be listed.

The ATEX Certificate

The ATEX Ex Product certificate in contrast to the CoC not contain the Manufacturing information. Therefore, this certificate is similar to the IECEx unit verification certificate.

After we go through the basics, let’s check the IECEx’s most complex kind of certification process.

Certificate of Conformity (CoC)

A certificate of conformity, or CoC, is requested by the Manufacturer of the Ex Product (via application form) and issued by the Certification Body (ExCB). The CoC states that the product meets the listed standards or tests in it.

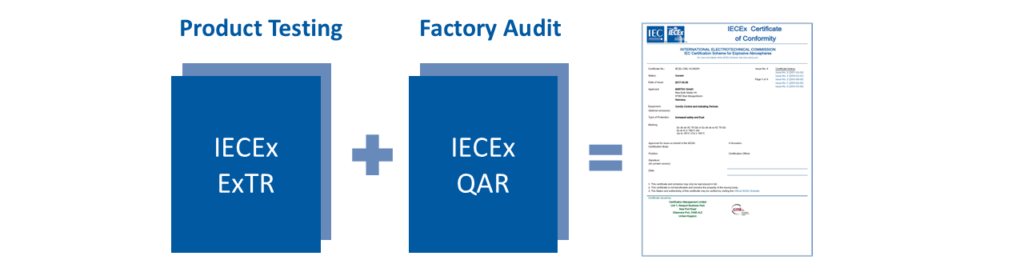

Two elements are required to get a CoC:

Test report (ExTR), based on type test(s) of the submitted products.

The factory’s Quality Assessment Report (QAR) – The manufacturing location of the product’s assessment and periodic surveillance. Stay tuned to our following blog post, because we will dive deep into the topic in Part.

If the results of these two elements are satisfactory, then a CoC can be issued and remain valid.

Test Report (ExTR)

An ExTR is not just one document, it is a document package. When your product wants to comply with multiple standards then this contains the following. A Cover with the test reports for the different standards that your product intends to be. Additional content can be the national differences of each applicable standard. After we are clear about the ExTR let’s check what needs to be submitted to the ExCB for the conformity of ExTR.

Preparation

For a PASS test report, the basic is that your product design complies with the standard’s requirement that your product intends to be used. Checklist a fundamental of it. Even under the design phase and even the document submission phase.

Challenges of Preparation

You were hasty at the interpretation of the standard(s) or checklist(s)

You prepare too many documents, which are hard to understand or systematize.

Not easily recognizable the Ex standard related information in the documentation

The more you are accurate with the product documents (schedule and related drawings), the easier the Certification Body’s work. With a good document pack, you can shorten the time associated with documentation verification.

Type Test Samples

Next to the documentation – that proves your product will withstand the standard’s requirements and the related test steps – you need to provide samples of your product. The ExCB will need physical proof of the correspondence of your product. For this verification usually, you need to provide the following:

An end product – a fully identical product to your design.

If special tests need to be performed on your product: a modified product. For example: your product’s protecting circuit needs to be tested, but for that, you need to modify the affected circuit. The key to the modified product: You must not change the logic and the function of your original protection in these product samples.

If your product contains electronic like PCB, you need to provide these components separately to the ExCB for measuring purposes.

Challenges of Type Test Samples

The factory background behind your product. In connection with QAR.

You do not check the required number of samples in the standard and you do not produce enough. The ExCB will request further samples, you need to produce them and this increases the timeline.

The cost of the samples. These products can’t be used for another purpose (especially the modified ones), so this will be a loss.

Next step

The CoC process is not complete without the Factory Certification Process (QAR). Many people mistakenly believe that once they design their product, prepare and submit the documentation, and send samples for type testing, they will receive their certificate. However, this is only the first step. In our next blog post, we will delve into the intricacies of QAR and the challenges it presents.

If you find this process overwhelming, don’t hesitate to reach out to our team of experts. We offer comprehensive support for your Ex Product certification journey, from start to finish.