Portable Remote Controller System

A user-centric design, ensuring an intuitive and seamless experience for operators. Leveraging our expertise in engineering solutions for hazardous environments, we employed innovative problem-solving techniques to address challenges such as wide operational temperature range, size constraints, and weight constraints. By fostering effective communication with our customer, we expanded the project to encompass a comprehensive Ex-system, which further enhanced the product's functionality and versatility.

Develop a cutting-edge Portable Remote Controller System for use in both explosive (Ex Zone1& Zone2) and non-explosive environments, meeting the unique requirements of marine, logistics, and oil & gas industries. Ensure compliance with stringent safety standards, prioritize a user-centric design, and deliver outstanding performance and reliability.

Meet international explosion-proof industry standards: IECEx, ATEX, UL913, UL & CSA, Inmetro, EACEx, and PCEC. Implement a procurement strategy to facilitate low-quantity production without compromising product quality and performance. Achieve a seamless integration of Ex hardware, touch screen display, and high-capacity Ex battery with Over-Current and Over-Voltage protection modules. Deliver a comprehensive product design for operational efficiency in both hazardous and non-hazardous environments.

Design and development of Ex Zone1 and Zone2 compatible Remote Controller System. Integrate Windows-compatible Ex hardware and touch screen display. Implement high-capacity Ex battery with Over-Current and Over-Voltage protection modules. Utilize Ultra High-Frequency radio communication for reliable data transmission. Precision engineering to meet size and weight constraints. Thorough testing and validation to ensure safety and compliance with industry standards. Provide comprehensive documentation, including explosive atmosphere certificates and safety manuals.

Features

- Ex-touch screen display design and procurement solution preparing

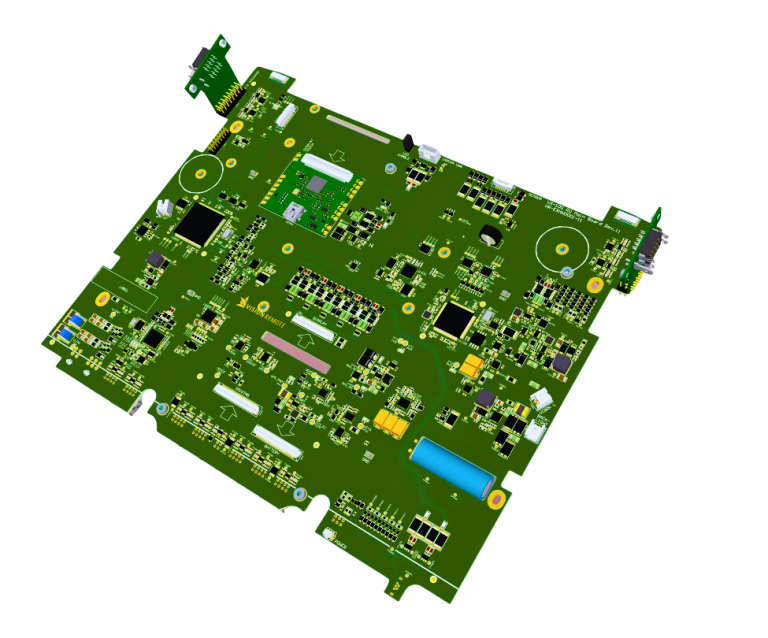

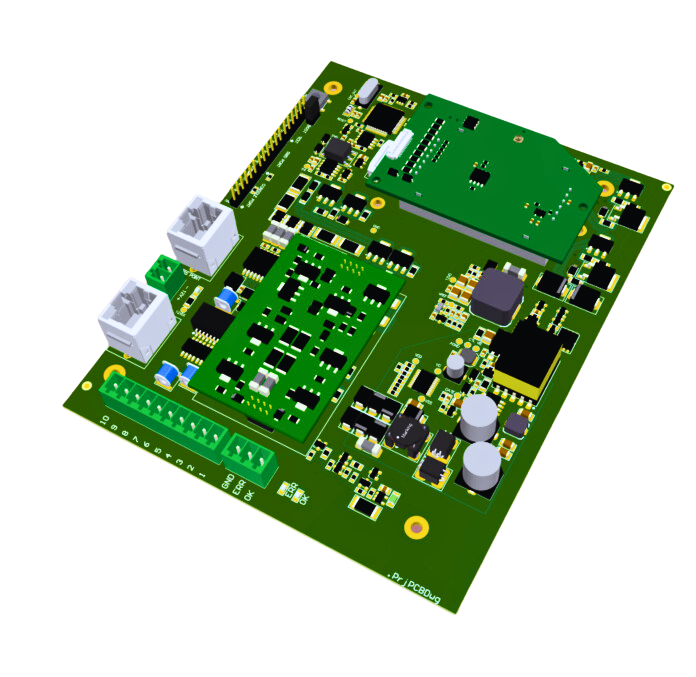

- Windows compatible Ex-hardware design

- Creating a high-capacity Ex battery

- Weight and size constraints

- Wide operational temperature range

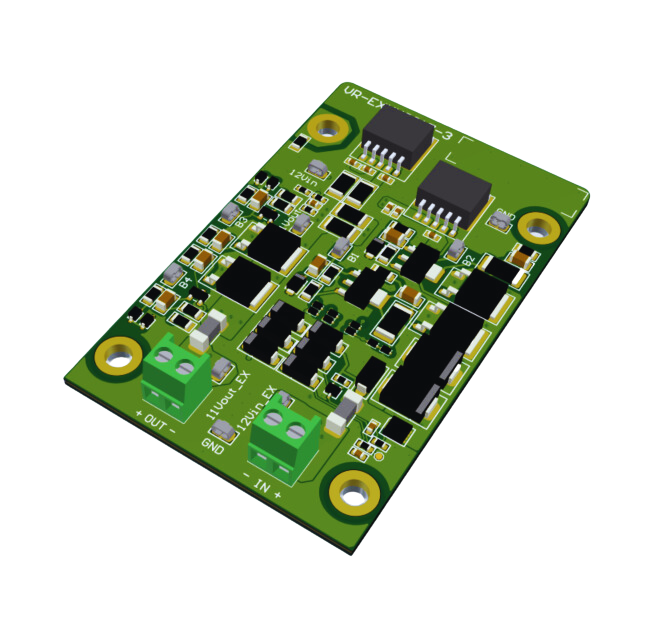

- Over-Current and Over-Voltage protection modules in the produc

- SAM ART Arm Cortex-M4

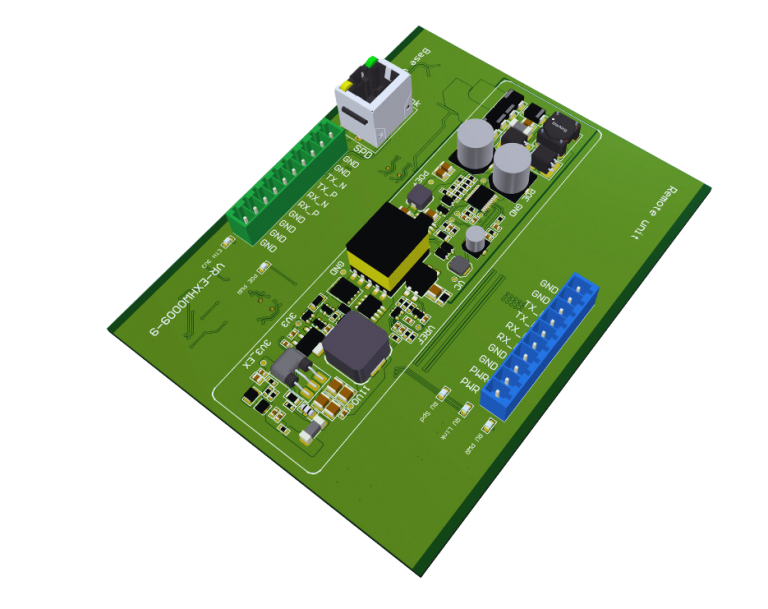

- Display Port, Ethernet Ex10/100, Sata M.2 and USB2.0

- LVD Interface and WIFi PCLe

- 8-layer PCB