- 2023-07-07

- Tamas Nagy

INTRINSIC SAFETY / ATEX / EX

At some workplaces explosive gases, vapors or dust/fibers may be present in the atmosphere (collectively refereed to as Explosive Atmospheres). Typical examples would be in the oil and gas industry, mines, chemical and pharmaceutical industry, mills, etc.

Combustion is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant (usually atmospheric oxygen), that produces oxidized, often gaseous products, in a mixture termed as smoke. Explosion can be looked at as a very rapid combustion, in which differences in pressure and/or temperature propagate rapidly. Supersonic explosions are called detonations.

Eliminate the presence of at least on of the following:

- Flammable/Combustible Material

- Oxygen

- Ignition Source

Different techniques to achieve the above targets are outlined in standards. One of the most widely recognized standard is the series of IEC 60079. Many localized standards are also derived from this international standard series, like for North America and Europe (ATEX Directive).

Eliminating the Presence of Flammable or Combustible Materials

…is by definition impossible, as we have have defined Hazardous Locations as places where these materials may be present in the atmosphere 😉

However industry standards are classifying these places into ZONES (IEC 60079-10) or DIVISIONS (NEC, NFPA 70 and CSA C22.1) based on the probability of occurrence of explosive atmospheres:

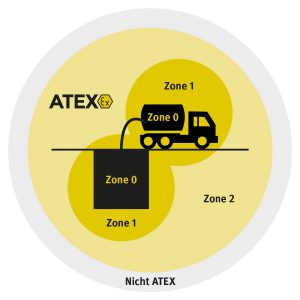

- ZONE 0 is where explosive atmosphere is present intentionally – like in fuel tanks or pipes for example.

- ZONE 1 is where explosive atmosphere shouldn’t be present by intent, but still there are high chances of leakages that may release explosive gases or vapors. A typical example would be the area around the tanks and pipes – especially around their interconnections, valves, etc.

- ZONE 2 is where explosive atmosphere is unlikely to be present, but not impossible. This area is usually further away from the locations of possible leakages, where the mixture of eventual explosive gases or vapors in the air are unlikely to reach concentrations that would create a hazard.

In North America DIVISION 1 used to cover ZONE 0 and ZONE 1, while DIVISION 2 is analogous to ZONE 2.

Eliminating the Presence of Oxygen and/or Explosive Gases

IEC 60079 series outline the techniques to eliminate Oxygen or explosive gases from the equipment where ignition sources may be present. Just a few examples:

- IEC 60079-1 Equipment protection by flameproof enclosures “d”

- IEC 60079-2 Equipment protection by pressurized enclosure “p”

- IEC 60079-5 Equipment protection by powder filling “q”

- IEC 60079-6 Equipment protection by liquid immersion “o”

- IEC 60079-7 Equipment protection by increased safety “e”

- IEC 60079-13 Equipment protection by pressurized room “p” and artificially ventilated room “v”

- IEC 60079-18 Equipment protection by encapsulation “m”

- IEC 60079-31 Equipment dust ignition protection by enclosure “t”

Eliminating the Presence of Ignition Sources

IEC 60079 series gives several possibilities for eliminating ignition sources from equipment. One of the most suitable for mobile equipment and the one that is applicable to all Zones is

IEC 60079-11 Equipment protection by intrinsic safety “i”

ADOTT Solutions specializes in equipment development that is compliant with IEC 60079-11. We have developed a patent pending solution for current and voltage limiting on intrinsically safe PCB-s. This allows high performing lightweight mobile electronic devices to be certified for use in hazardous areas, which was not possible before.

We are also pioneering in developing and certifying high capacity rechargeable batteries that are certified for use in Zone0, Zone 1 and Zone 2 in explosive atmospheres, according to European ATEX directive and based on IEC 60079-11 standard. We use cells that can be even punctured or mechanically damaged, and will still not get into the runaway state to catch fire or explode.

Images used courtesy of Envato.